Products List

Our outstanding performance in all aspects of Quality (Q), Cost (C) and Delivery (D) has earned us a high reputation from the world’s car makers as a reliable supplier of suspension parts in Japan.

Car

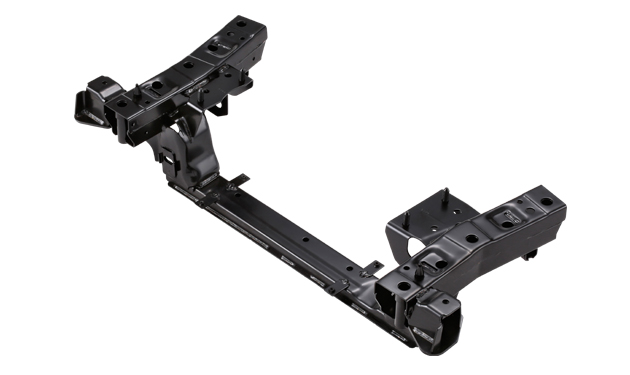

Front Suspension Member

This is a front suspension member combining the left and right side members and the front/rear cross members into a single unit.

By joining side members, a front cross, and a rear cross of different thicknesses into a tailored blank, it is possible to assign an individual thickness for each part, thereby achieving greater stiffness and reducing weight.

This is a stiff front suspension member with six mounting points. Placing a U-shaped pipe with superior stiffness performance in the basic framework and running an A-shaped pipe through it generates an extremely high degree of stiffness. Thanks to this stiffness, the thickness of the steel sheet can be reduced, bringing the weight down.

This is a front suspension member comprising three sections: stiff left and right side members and a thin plate cross member.

Because the side members that cut across the car lengthwise efficiently transmit input from the road to the body, the thickness of the cross member can be reduced, thereby reducing the weight.

This is a front suspension member with vertical lower link fasteners. The number of components and weight were reduced thanks to the elimination of special fastening parts (brackets) by using the upper panel and lower panel as fastening members for the lower links.

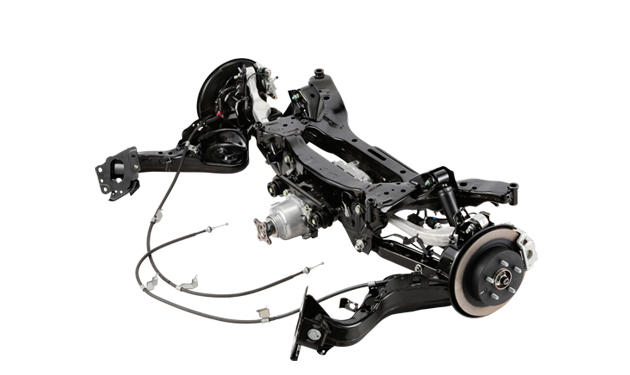

Rear Suspension Member

This is a stiff rear suspension member with six mounting points.

The placement of pipes with excellent stiffness performance near the input points achieves a 3-dimensional mezzanine structure with an extremely high degree of stiffness.

Rear Beam

This is a rear beam axle in which the left and right trailing arms and crossbeam have been made into a single unit.

By joining trailing arms and a crossbeam of different thicknesses into a tailored blank, the load from the tires can be transmitted effectively and stiffness can be increased while weight is decreased.

This is a rear beam axel in which pipes made of curled steel plate are used for the left and right trailing arms.

Curling steel plate enables perimeter changes, expanding freedom in designing the cross-section of positions requiring strength and stiffness. It also enables inexpensive manufacturing, bringing costs down.

Links

This is a front lower link with a single plate structure.

Making all the fasteners to the front member vertical eliminates the need for special fastening parts (collars) and reduces the number of parts and weight. Moreover, the single plate structure eliminates the welding process, reducing costs.

This is a front lower link made from 780 MPa-grade ultra-high tensile steel.

Developing a product form and manufacturing process that take full account of the material properties of high tensile steel enabled the use of thinner steel, taking advantage of its high material strength, thereby reducing weight.

This is a lower arm that uses reverse flanges.

Reverse flanges, in which flanges are bent further inward at points on which the vehicle's longitudinal force acts, enable greater strength in a single plate structure.

This is a trailing arm in which pipe is used for the structural members.

Optimal sectioning and a lower weight are achieved by shaping the pipe with hydroforming.

Brake pedal

This is a brake pedal that suppresses retreat of the pedal during a collision.

The built-in retreat suppression system kicks in during a collision, moving the pedal lever toward the front of the vehicle and softening the impact on the driver's foot.

It also uses a link structure that enables powerful braking force with a short stroke.